Polymer foam materials, the rising star in new materials, unlock game-changing properties in polymers via versatile foaming technologies. Their winning features—lightweight design, shock absorption and noise reduction, thermal insulation, and filtration, position them as indispensable solutions across vertical application domains.

As the leading exhibition platform for Asia's foam industry, Interfoam has long been at the forefront of foaming technology innovation. Foam materials, with their exceptional performance, are playing a pivotal role in numerous industries. Interfoam will persist in fostering the practical application of foam materials across diverse sectors, empowering exhibitors to forge valuable partnerships and guiding visitors to discover cutting-edge foaming solutions.

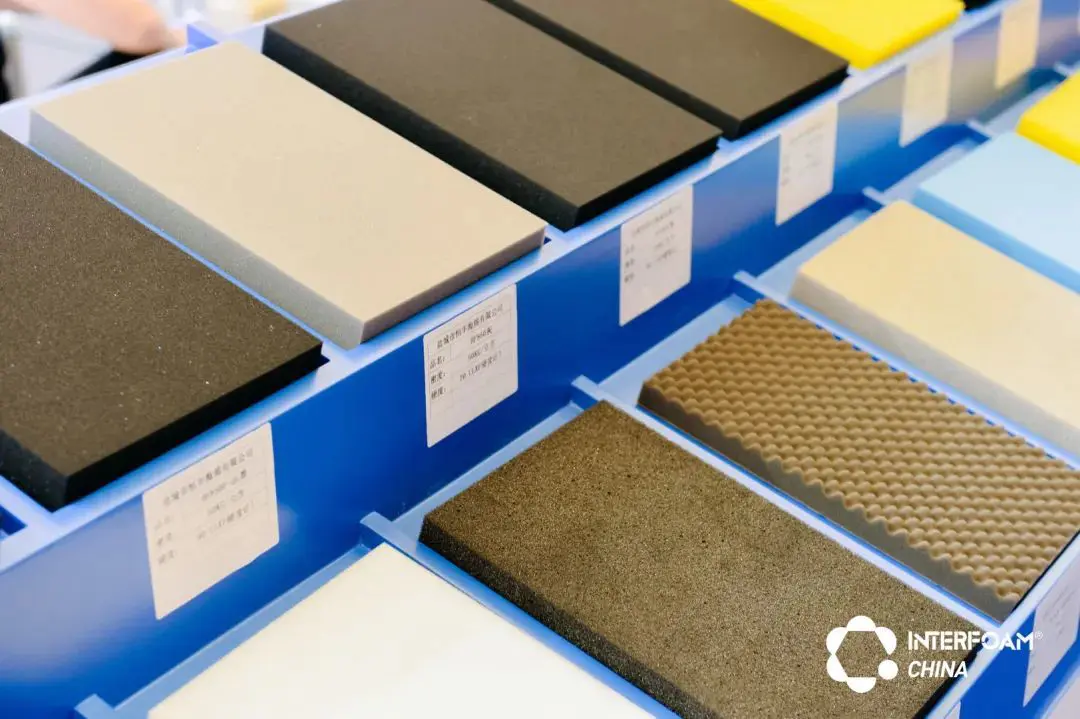

“Technical Foams”

Polyurethane, polyolefin, silicone, rubber, polystyrene, polyvinyl chloride (PVC), elastomer, melamine, polyimide, polymer blends, biobased and biodegradable polymeric foaming materials and products; metallic and inorganic foaming materials and products.

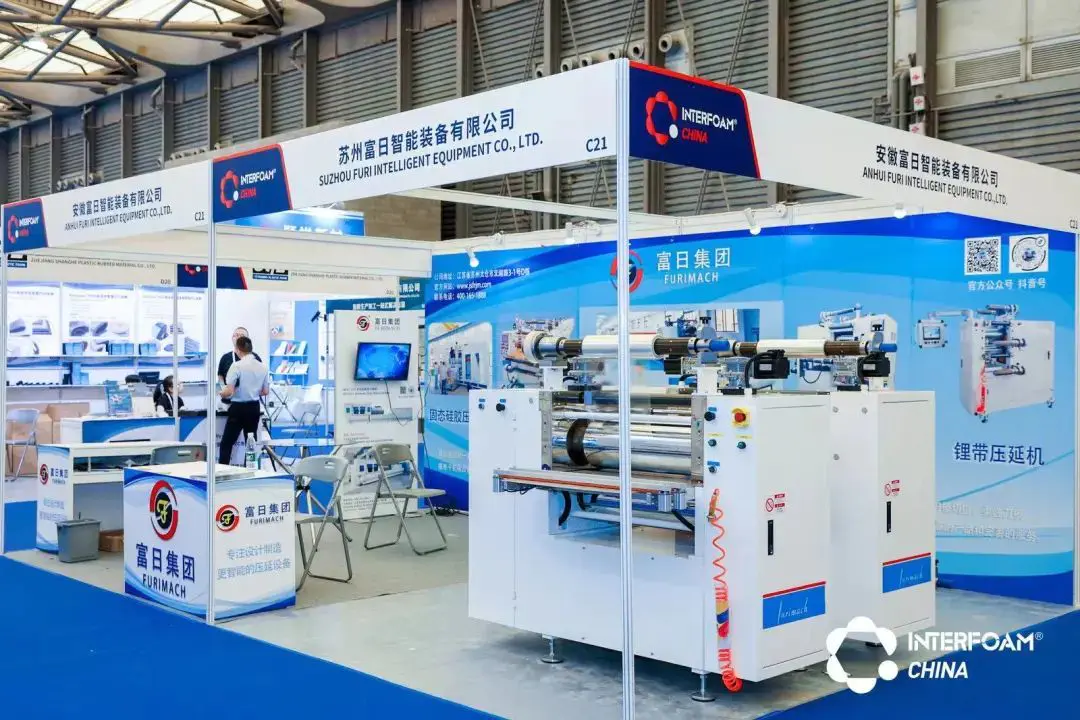

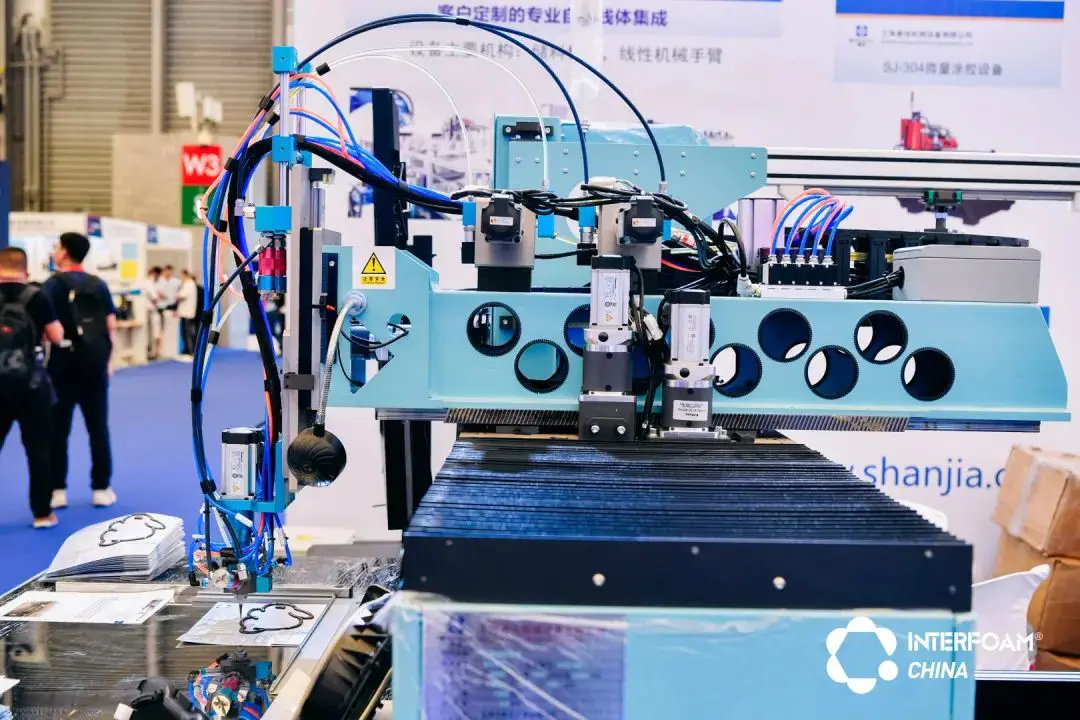

“Technologies and Equipment”

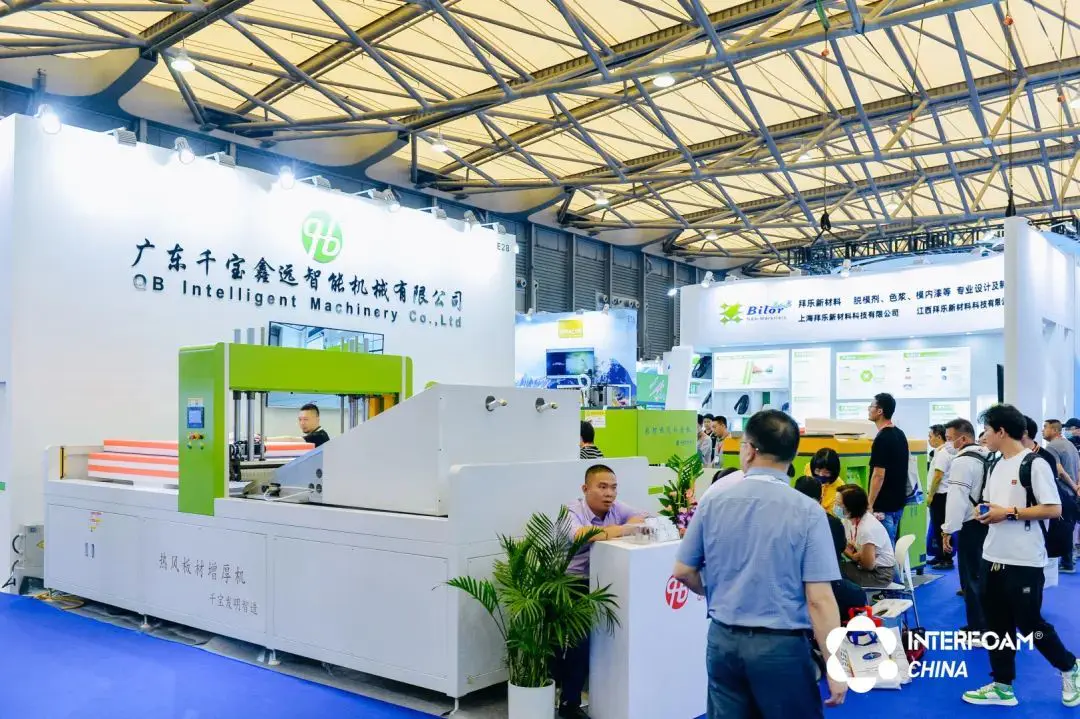

Foaming equipment, auxiliary equipment, cutting equipment, testing equipment, recycling equipment, environmental protection equipment, molds, cutters, etc.

“Raw Materials, Foaming Agents and Additives”

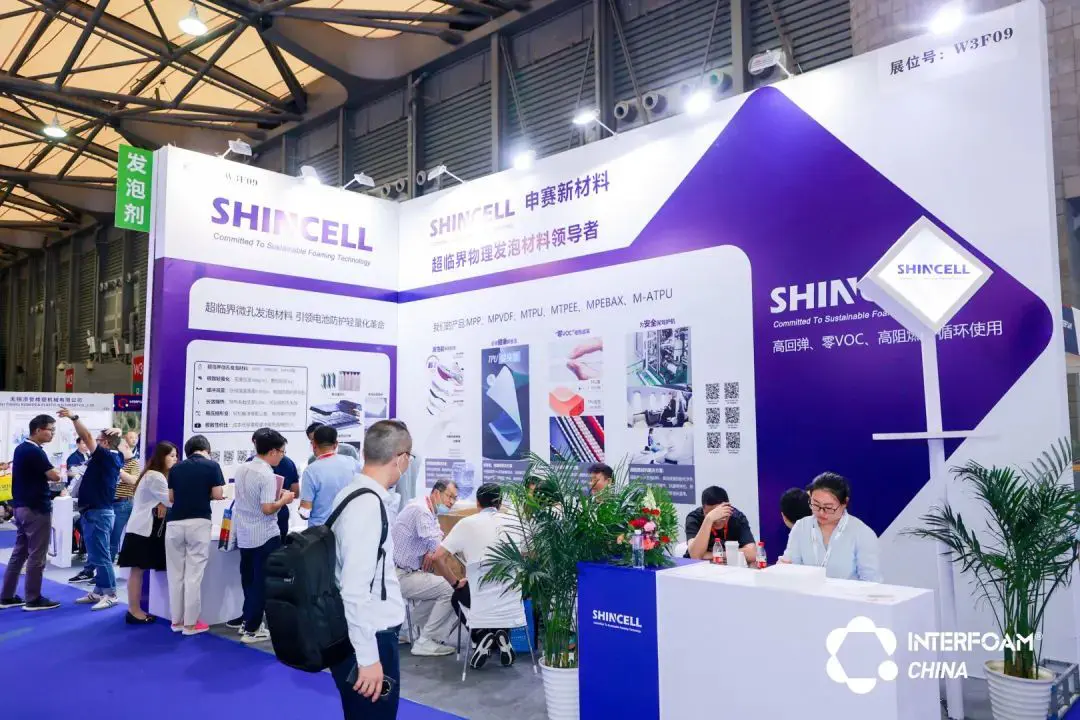

Foaming raw materials, compound materials, physical foaming agents, chemical foaming agents, industrial gases, additives, etc.

“Processing and Services”

Material compounding, cutting, die-cutting, contract manufacturing, technical consultation and services, etc.

A Trade Show Platform for Facilitating Transactions and Driving Cost-Effective Efficiency

As the leading exhibition platform for Asia's foam industry, Interfoam has long been at the forefront of foaming technology innovation. Foam materials, with their exceptional performance, are playing a pivotal role in numerous industries. Interfoam will persist in fostering the practical application of foam materials across diverse sectors, empowering exhibitors to forge valuable partnerships and guiding visitors to discover cutting-edge foaming solutions.

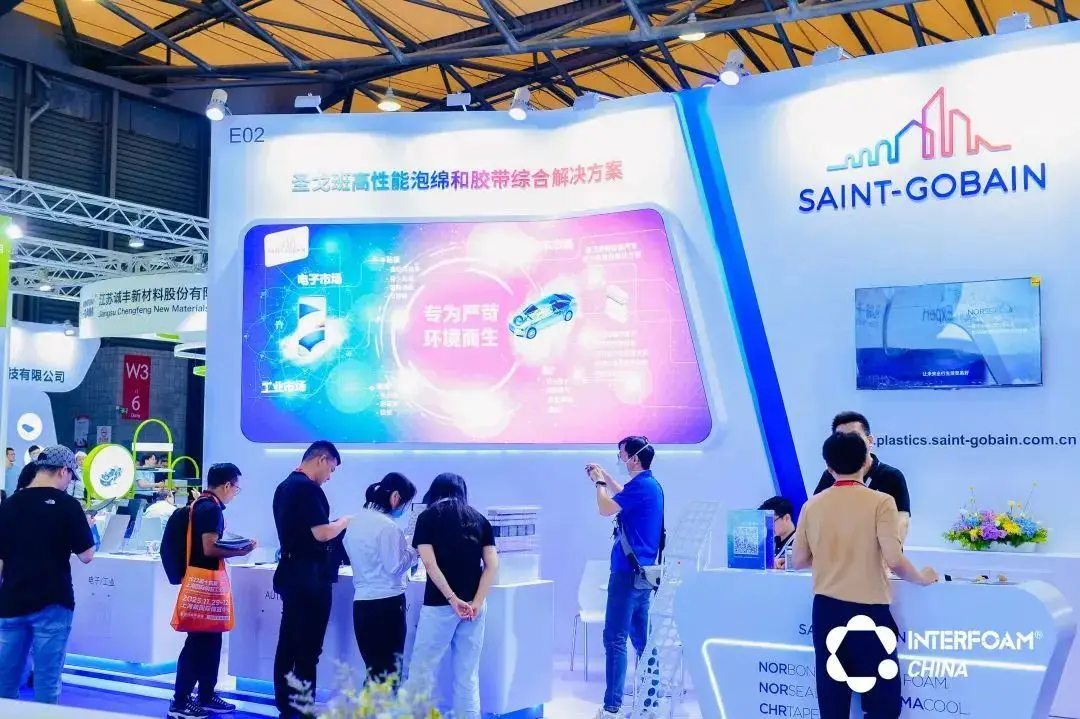

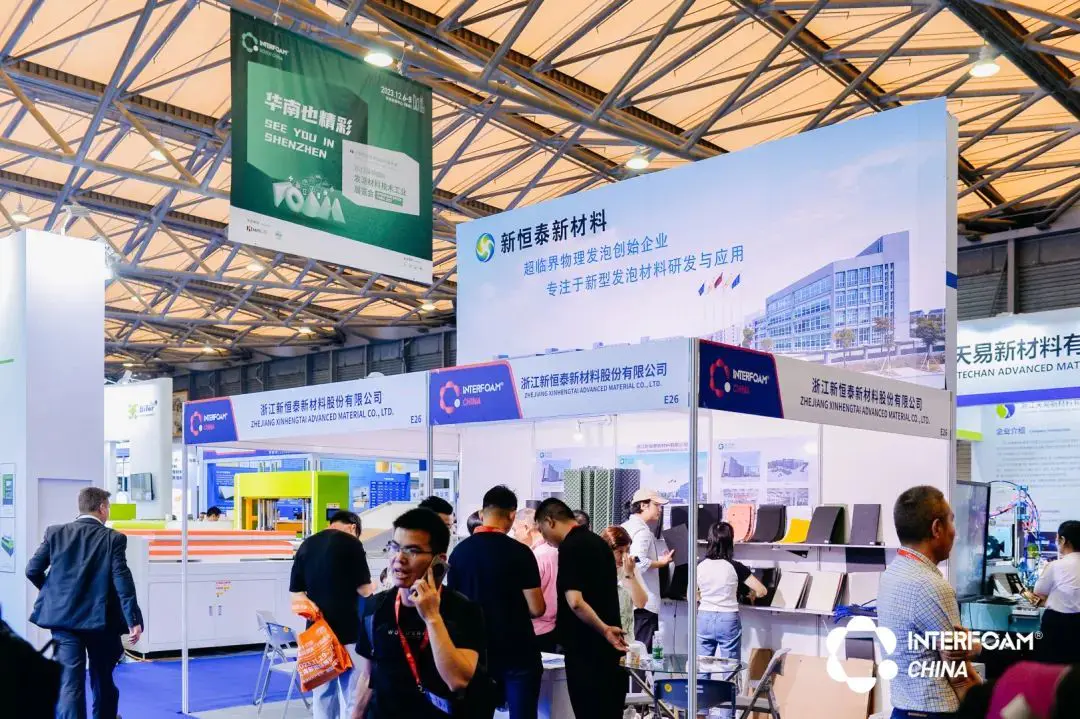

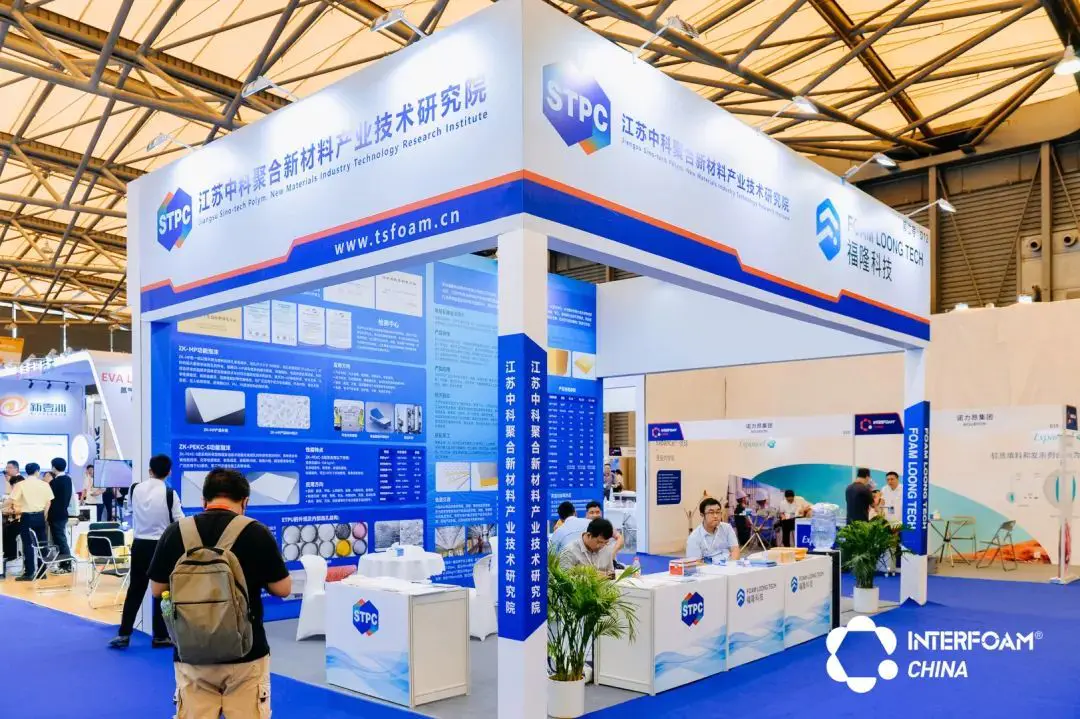

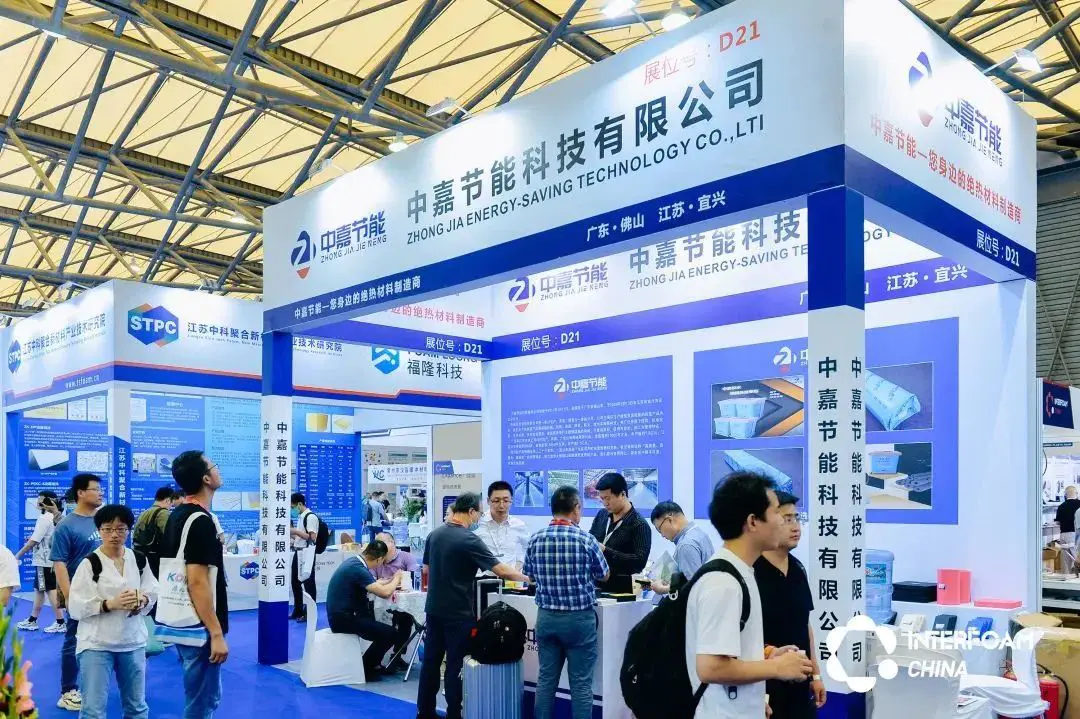

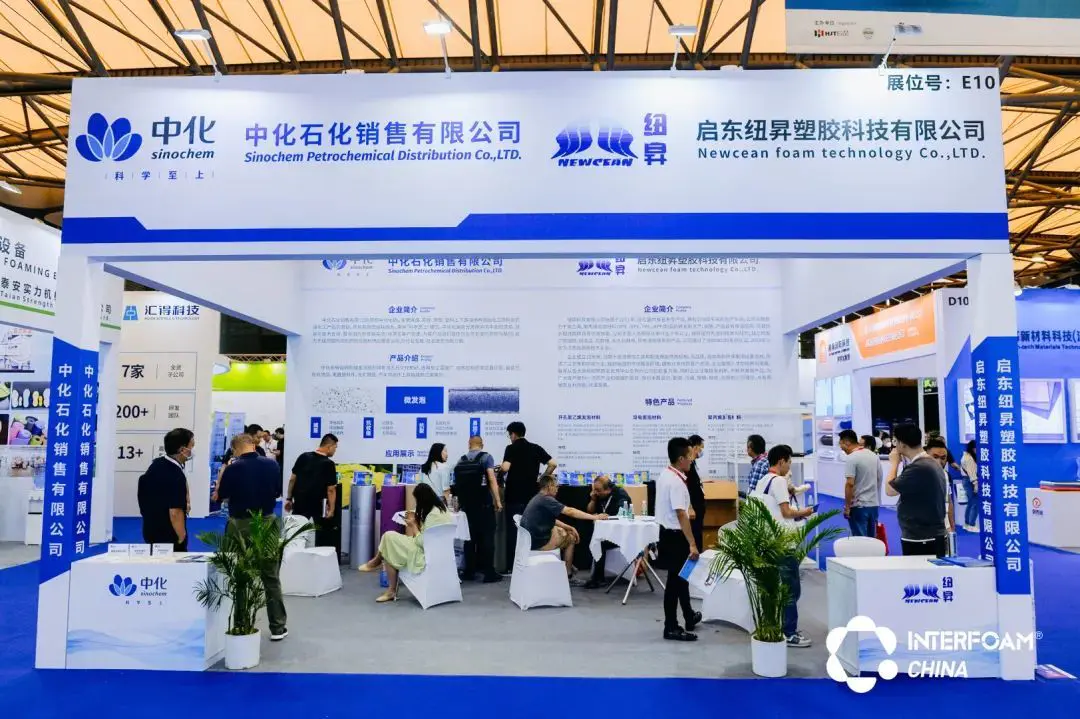

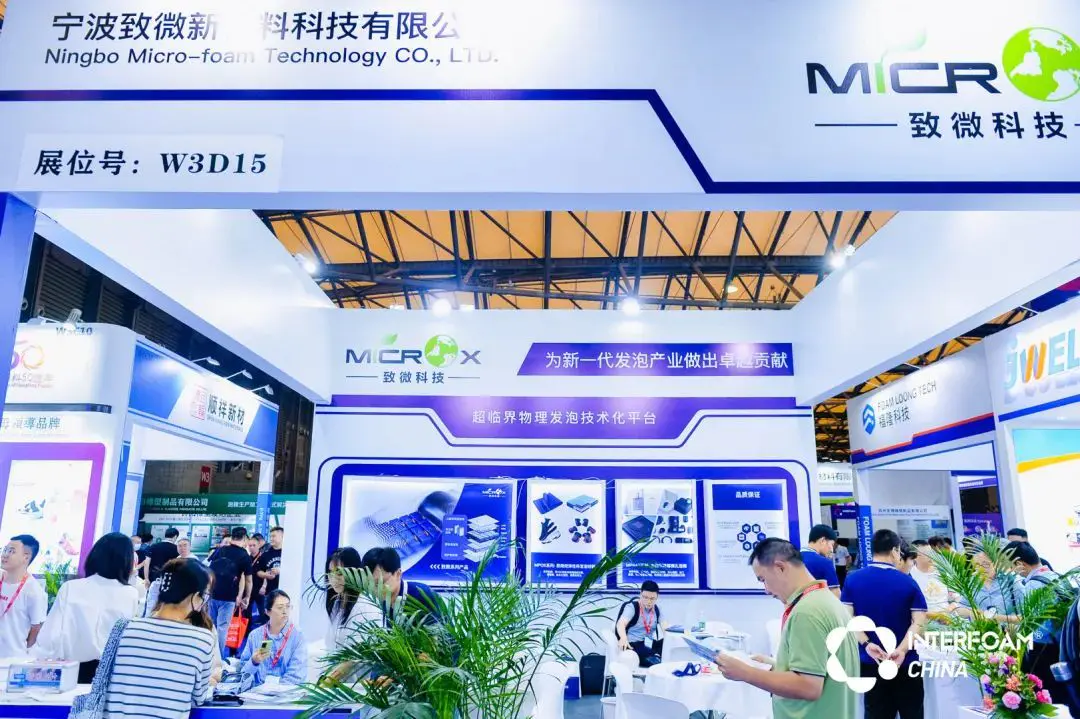

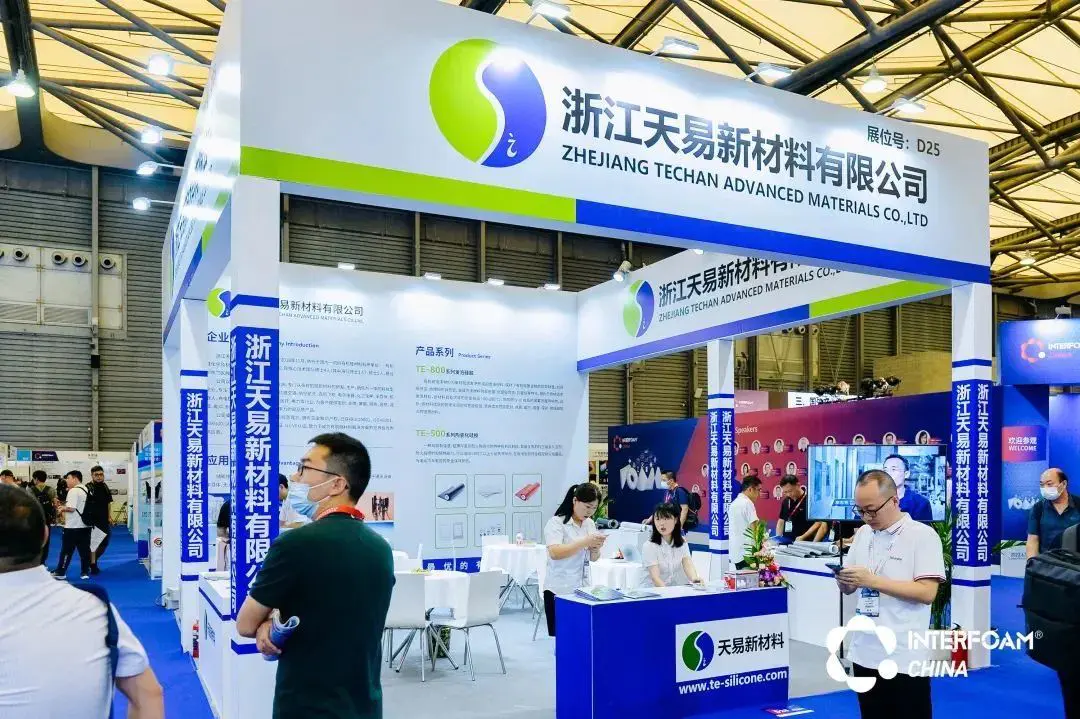

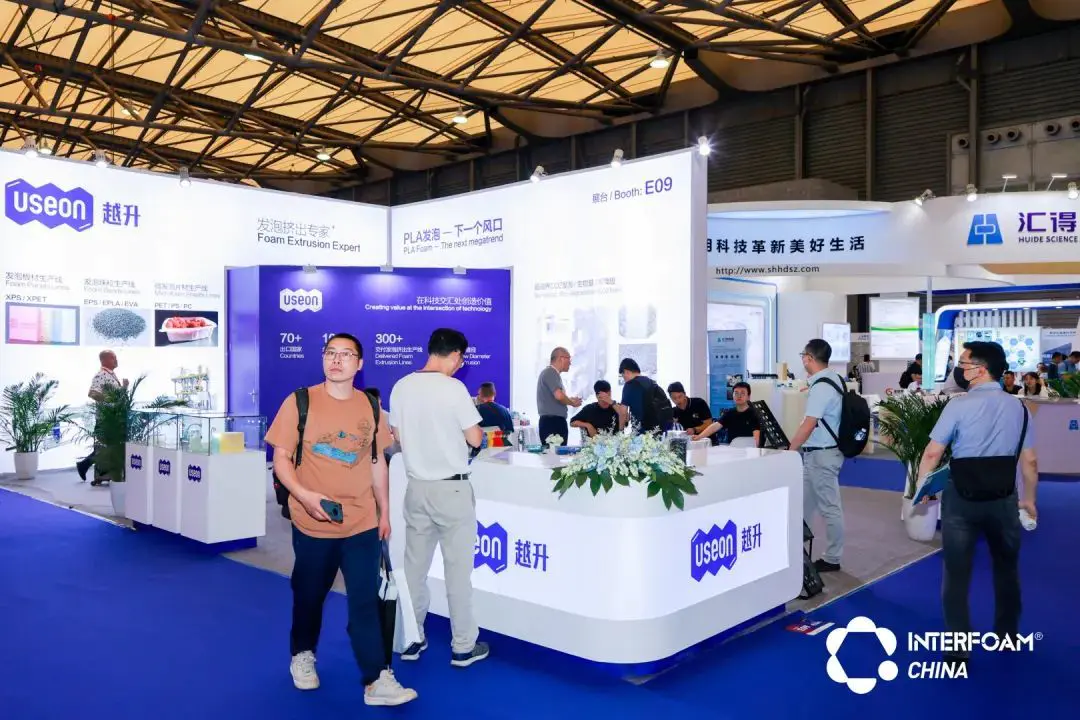

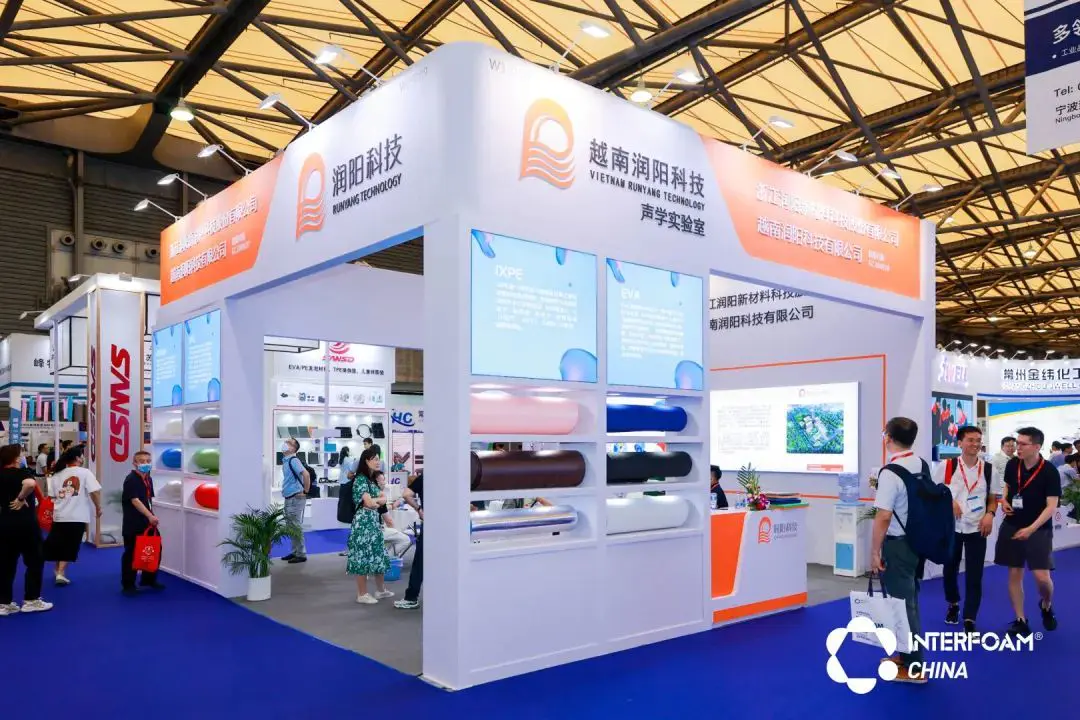

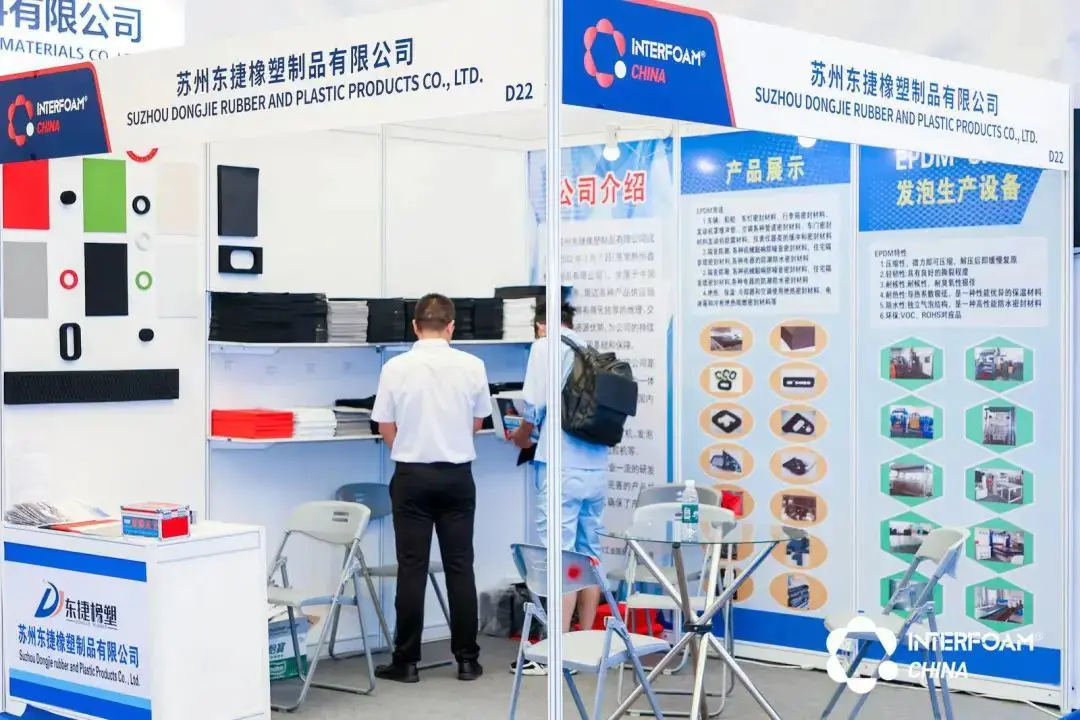

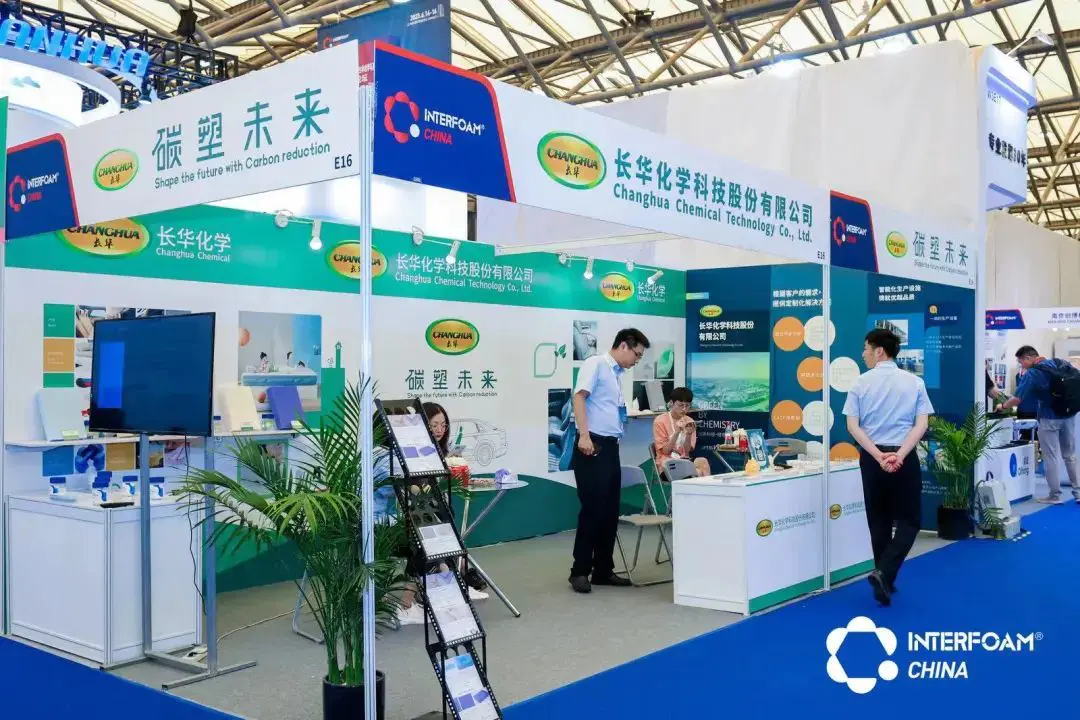

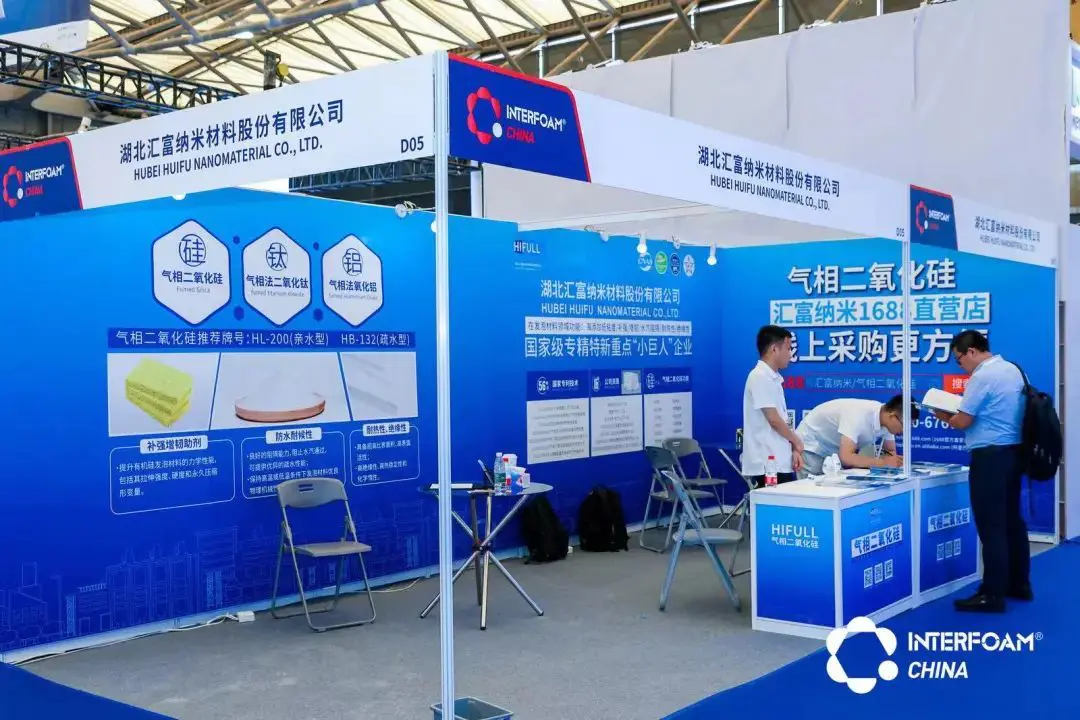

Key Exhibitors

"Redefine Foams" The 5th Foams and Application International Forum

Based on the theme of last forum—"Redefine Foams", this forum will, from the dimensions of sustainable development, academic research, technical innovation and new applications, discuss the innovation and development of foams and their vertical applications. We will create a positive exchange platform for enterprises, universities, and research institutes, which will cover about 100 topics and be held on-line and off-line simultaneously.

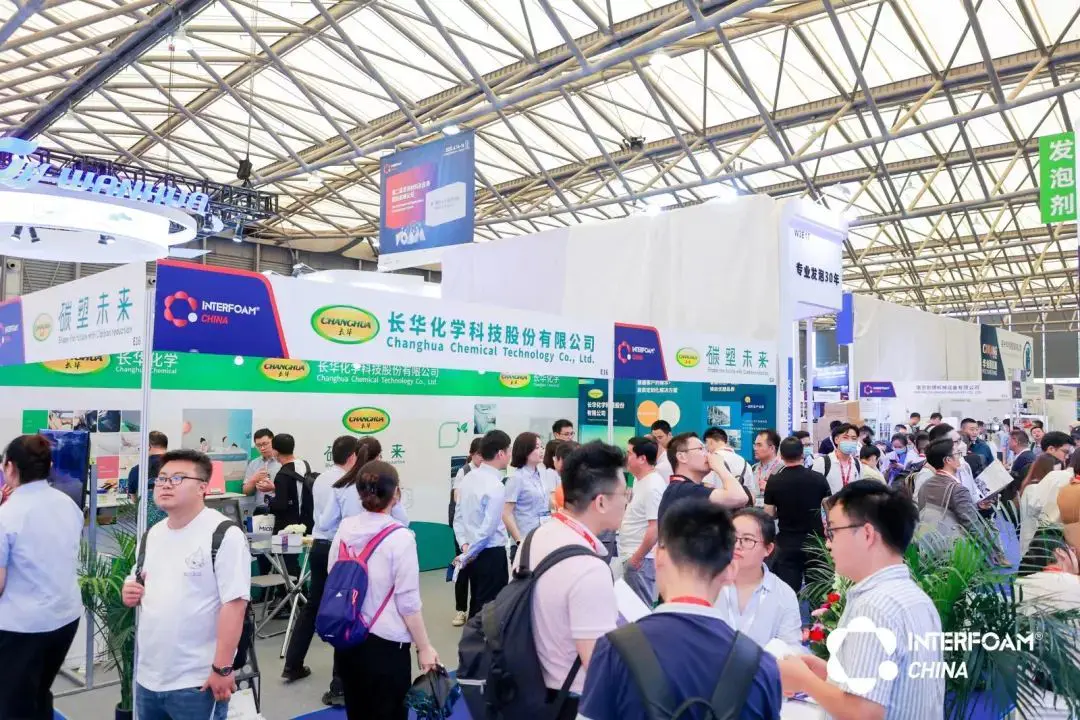

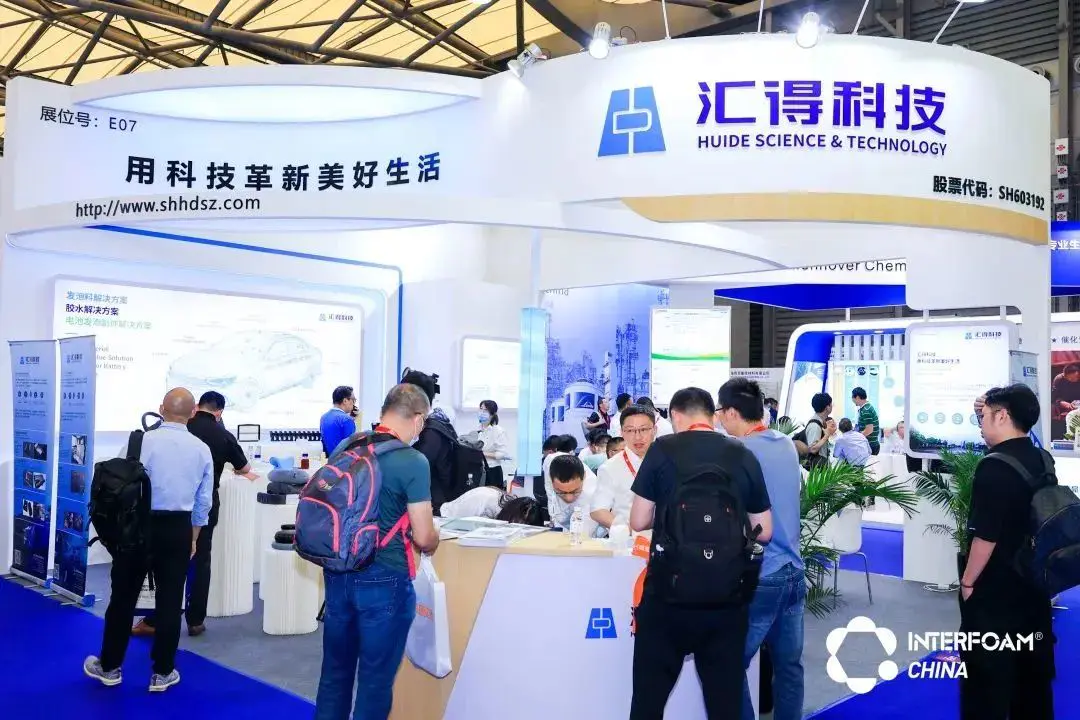

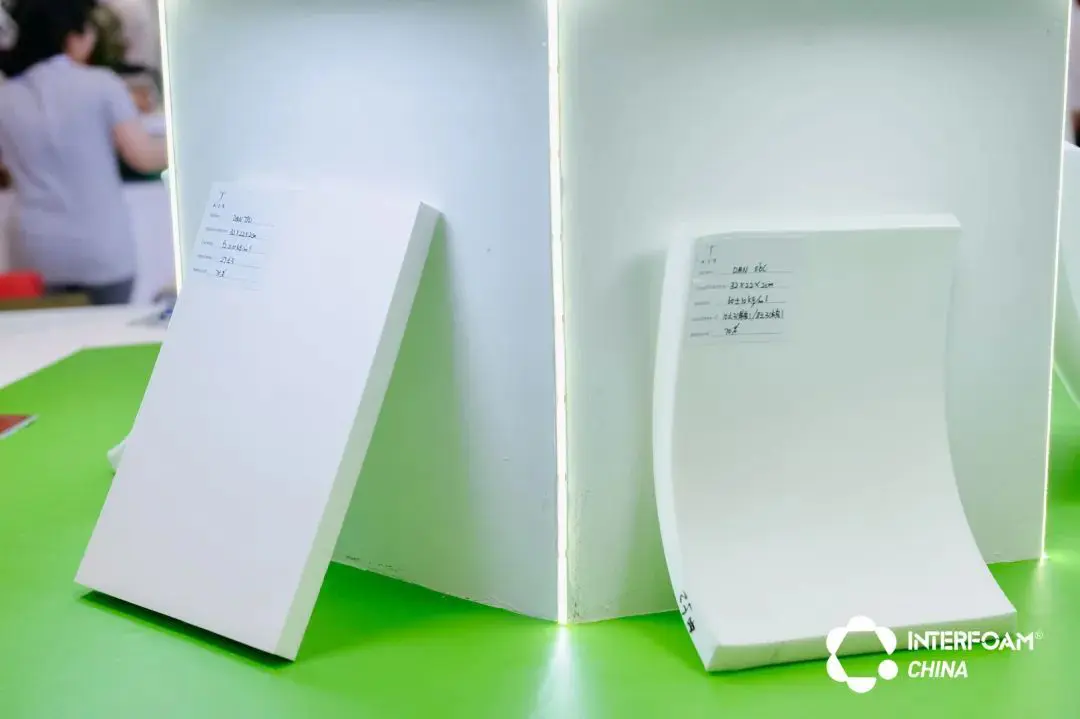

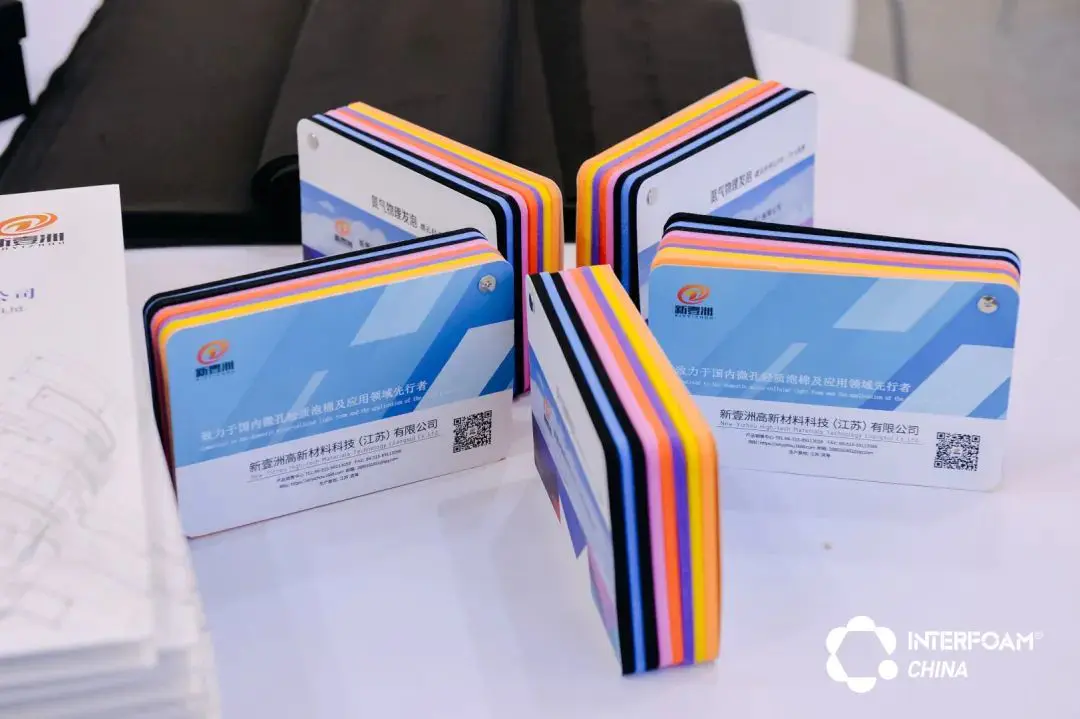

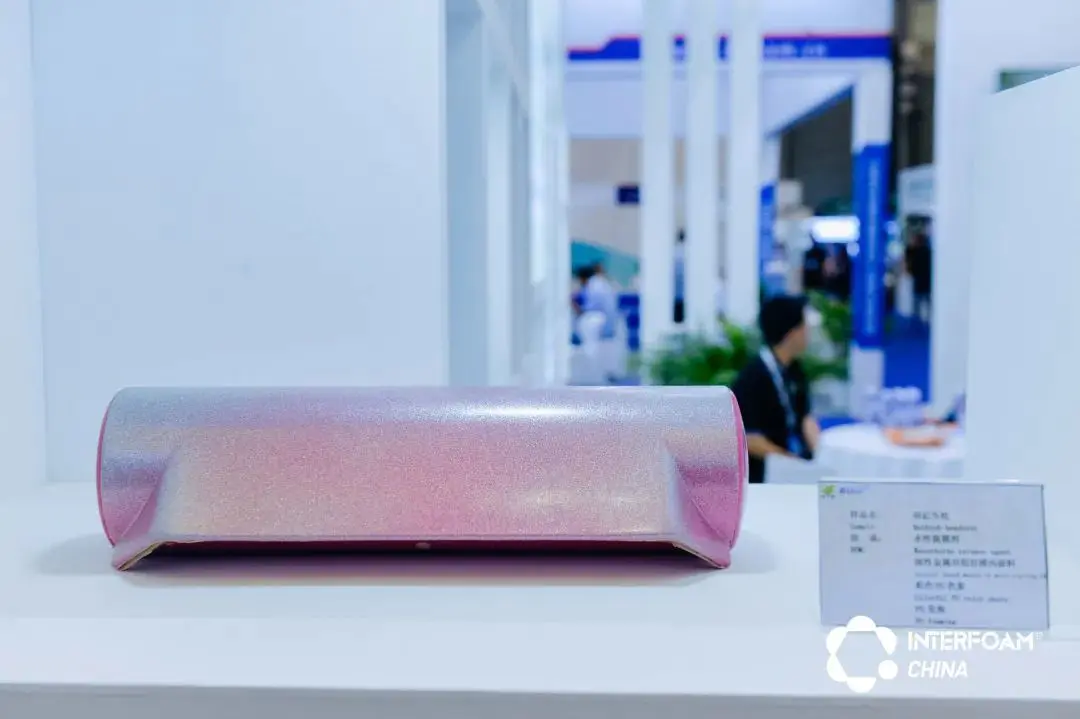

Glimpse of Interfoam China

Media Partners

Please browse vertically for better experience.