薛佳 女士

数据中心高级经理,北京汇捷通国际展览有限公司

| 电话 | +86 21 63232733 |

|---|---|

| 传真 | +86 21 63232733 |

| 邮箱 | katelyn.xue@interfoam.cn |

| 地址 | 上海市黄浦区广东路500号世界贸易大厦5层 |

ALFA Klebstoffe AG

展位号:E18

01

配方不含VOC的胶粘剂

VOC-free formulated adhesives

Due to new regulations and export guidelines, limit values for VOC are being set ever lower. Manufacturers who bond their foams with solvent-based and therefore VOC-containing adhesives are faced with ever greater challenges in meeting these limits. SIMALFA® offers future-oriented solutions with added value since 1990 and avoids VOC-containing ingredients in its water-based adhesives for foam-bonding.

根据新出台的法规和出口指导意见,挥发性有机化合物(VOC)的限值越来越低。使用溶剂基粘合剂(即含有VOC的粘合剂)粘合泡沫的制造商在满足这些限值方面面临着越来越大的挑战。自1990年以来,SIMALFA®就一直提供面向未来的增值解决方案,并在其用于泡沫粘合的水基粘合剂产品中避免使用含有VOC的成分。

什么是VOC?

WHAT IS VOC?

VOC are volatile organic compounds which become gaseous already at room temperature. VOC often have a harmful effect on people and the environment or cause unpleasant odours. These, sometimes poisonous, substances are volatilized only after hours or days and are partly responsible for the greenhouse effect. VOC can also cause various health problems for humans. This increases the public and governmental pressure on producers worldwide to avoid VOC-containing ingredients.

VOC全称为挥发性有机化合物,它在室温下就已呈气体状态。VOC通常会对人和环境产生有害影响,或者产生令人不快的气味。这些时而有毒的物质只有在几小时或几天后才会挥发,是产生温室效应的部分原因。VOC也会给人类带来各种健康问题。因此,公众和政府不断给全球的生产商施加压力,要求他们避免使用含有VOC的成分。

SIMALFA®胶粘剂生产过程不含VOC

SIMALFA® ADHESIVES PRODUCED WITHOUT VOC

SIMALFA® is produced without adding VOC and is tested for pollutants. Independent laboratory analyses confirm that SIMALFA® meets demanding standards. Thus, governmental requirements are exceeded, the environment is preserved and your employees are protected.

SIMALFA®的生产过程不添加VOC,且经过污染物测试。独立的实验室分析证实,SIMALFA®符合严格标准。因此,它极大地满足了政府要求,同时也能保护环境及公司员工。

特征或优势:

<REGULATIONS AND CERTIFICATES>

The following guidelines and requirements of ECO-labels are fulfilled by SIMALFA®:

<法规和证书>

SIMALFA®满足欧盟生态标签ECO-Label的以下指导意见和要求:

TVOC (IOS-MAT-0010)

ECO-Passport(生态环保认证)

Green Guard(美国绿色卫士室内空气质量认证)

HJ2541-2016

GB 33372- 2020

Nordic Ecolabelling(北欧生态标签)

应用领域:

- Spray application for foam-bonding (ex. upholstery)

- Roller coating for foam-bonding (ex. mattresses)

- 用于泡沫粘合的喷涂应用(例如室内装潢)

- 用于泡沫粘合的滚涂(例如床垫)

案例或解决方案:

When changing from solvent-based adhesives to water-based adhesives from SIMALFA® you not only improve the pollutant balance of your products and protect your employees, you also simplify the handling with the adhesive. For transport and storage no precautions or protective measures are necessary. Maintenance work is not necessary and the production environment can be kept clean easily.

如果弃用溶剂基粘合剂,转用SIMALFA®品牌的水基粘合剂,不仅可以改善产品的污染物平衡,保护员工,还能简化粘合剂的处理。对于运输和存储,无需采取任何预防或保护措施。无需维护工作,可轻松保持洁净的生产环境。

Our adhesive experts help you to change from solvent-based adhesives to SIMALFA®. Avoiding VOC and other pollutants creates significant added value and makes your company more competitive in every way.

我们的粘合剂专家将竭诚帮助您从溶剂基粘合剂过渡到SIMALFA®粘合剂。避免使用VOC或其他污染物将为您创造显著的附加值,提升公司在各方面的竞争力。

02

无过喷泡沫胶粘剂

Overspray Free adhesives for foam-bonding

Adhesive-users constantly face the problem that overspray arises during application. This “side effect” generally arises in the case of dispersion adhesives due to viscosity and other factors. Material that occurs as overspray is not used and gets lost.

胶粘剂用户在工作过程中常常会遇到过度喷胶的问题,这种副作用通常出现在由于粘度和其他因素引起的分散胶粘剂的情况下,这一问题通常会导致胶粘剂未被充分利用而出现浪费。

解决方案 :

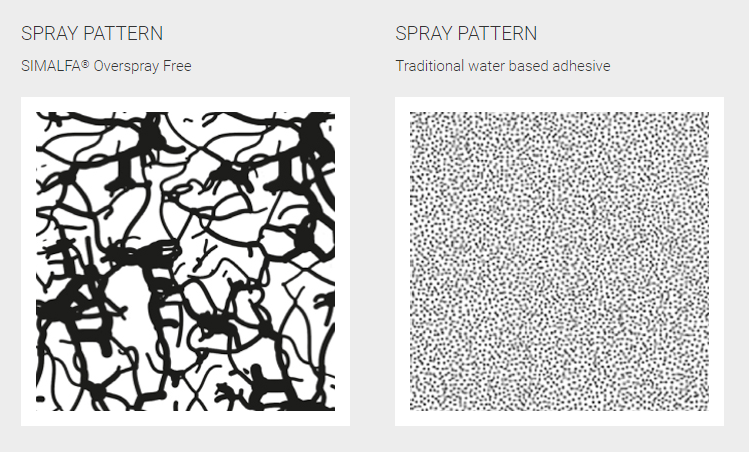

The SIMALFA® Overspray Free Technology generates a net-like spray pattern during application. This prevents individual adhesive particles from swirling and producing overspray. With this new OF technology, foam and upholstery materials can be bonded immediately without producing overspray. A real guarantee for a clean and safe working environment. And best of all: This technology is now also available for the first time for 2-component systems.

SIMALFA® 无过喷技术可以让喷枪在使用时喷胶生成网状。这可以防止单个粘附颗粒旋转和产生过量喷雾。有了这种新的OF技术,泡沫和室内装饰材料可被瞬间粘合而不产生过喷,这为清洁和安全的工作环境提供了切实保障。最重要的是: 这一技术现在也首次应用于双组分系统。

特征或优势:

Clean working surfaces and environment

High precision

Less adhesive waste

Less maintenance work

Different application options (automatic spray application)

清洁的工作台面和环境、高精度、极少浪费、极少的维护工作、多样工具可选(自动喷胶系统)

应用领域:

AREAS OF USE

Foam converting

Mattresses

Upholstery industry

Transportation

Packaging, etc.

泡沫加工、床垫、室内装潢业、运输、包装等

MOST BONDED MATERIALS

Used for all kinds of upholstery applications and materials, such as foams, cloth, polyester wool, cotton, wood, plastic, cardboard, rubber, leather, artificial leather or non-woven.

最常见应用:用于各种室内装潢应用及材料,如泡沫、布、涤棉、棉、木、塑料、纸板、橡胶、皮革、人造革或无纺布等。

APPLICATION TYPES

Spray guns

Automatic spray application

Automatic application rollers

Manual with brushes

涂布方式

喷枪

自动喷涂设备

自动辊涂设备

手工刷涂

案例或解决方案:

The SIMALFA® Overspray Free Technology generates a net-like spray pattern during application. This prevents individual adhesive particles from swirling and producing overspray. With this new OF technology, foam and upholstery materials can be bonded immediately without producing overspray. A real guarantee for a clean and safe working environment. And best of all: This technology is now also available for the first time for 2-component systems.

SIMALFA® 无过喷技术可以让喷枪在使用时喷胶生成网状。这可以防止单个粘附颗粒旋转和产生过量喷雾。有了这种新的OF技术,泡沫和室内装饰材料可被瞬间粘合而不产生过喷,这为清洁和安全的工作环境提供了切实保障。最重要的是: 这一技术现在也首次应用于双组分系统。

03

SIMALFA®无CR泡沫胶粘剂

SIMALFA® CR-FREE ADHESIVE

SOLUTIONS FOR FOAM-BONDING

Introducing SIMALFA® CR-free adhesives – the first CR-free one- and two component adhesives for foam-bonding. The ecological and economical portfolio of the new adhesive technology optimally complements the existing SIMALFA® product range and covers todays and future needs of the industry. Furthermore, the state-of-the-art CR-free formulations are completely non-yellowing and aging resistant.

SIMALFA®无CR胶黏剂是首创的无CR单组份及双组份胶黏剂,适用于泡绵行业的黏接使用。该新型黏合剂技术既生态环保,又经济实惠,完美补充了现存的SIMALFA®产品系列,契合当下和未来的行业需求。此外,该先进的无CR配方完全不会黄变和老化。

CR是什么?

WHAT IS CR?

Chloroprene Rubber (CR) plays a major role in the global economy, with key applications in various industries including manufacturing, automotive, medical industries and consumer goods. It is mainly used for the production of technical rubber parts (cables, hoses, belts, etc.), neoprene and water-based adhesives.

When formulating water-based adhesives, CR is very popular for its good bonding properties and is used in most products today.

氯丁橡胶(CR)在全球经济中发挥着重要作用,广泛用于制造业、汽车、医药、消费品等多个行业。主要用于生产技术橡胶零件(电缆、软管、皮带等)、合成橡胶及水性胶黏剂。

在制备水性胶黏剂时,CR因其良好的黏接性而广受欢迎,目前已广泛应用于行业内大多数产品。

BENEFITS OF CR-FREE ADHESIVES:

- Most advanced chlorine-free formulation

- Highly economical and ecological

- Non-yellowing and aging resistant

- Energy-saving production

- Meets environmental guidelines

- Resource-saving manufacturing process

无CR胶粘剂的优势

-最先进的无氯配方

-高性价比和高环保性

-耐黄变、耐老化

-生产过程节约能源

-符合环保指南

-制造过程节约资源

AREAS OF USE

Foam converting

Mattresses

Upholstery industry

Transportation

Packaging, etc.

应用领域:

泡沫加工、床垫、室内装潢业、运输、包装等

领先的无CR胶粘剂系列产品

THE LEADING CR-FREE ADHESIVE PORTFOLIO

The SIMALFA® CR-free adhesives are available as both 1-component and 2-component adhesives. As with all SIMALFA® adhesive types, the new series is extremely economical to use. Even smallest application quantities efficiently bond foams and enable bonding at the highest level.

SIMALFA®无CR系列粘合剂分单组份和双组份两大类。与所有的SIMALFA®粘合剂一样,该新系列产品具有超高性价比。即使是极小的用量也能高效粘合泡绵,并能实现最佳的粘合效果。

The CR-free adhesives from SIMALFA® are water-based contact adhesives, formulated free of solvents and halogen (and as a result free of chlorine). The adhesives were developed especially for the foam processing industry. The one- and two-component system can be used for a multitude of materials produced by the foam converting and upholstery industry.

SIMALFA® 的无 CR 粘合剂是水基接触粘合剂,不含溶剂和卤素(因此不含氯)。该粘合剂是专门为泡沫加工行业开发的。单组分和双组分产品可用于泡沫加工业和室内装潢业生产的多种材料。

The adhesives are characterized by excellent wet adhesion and heat resistance. Together with the high initial tack, the user benefits from a system that guarantees both economic and ecological processing.

该胶黏剂具有良好的湿附着性能和耐热性。外加极其出色的初黏性,该产品在环保无污染的同时又具有高性价比,可让用户从中大大受益。

减少你的生态足迹

REDUCE YOUR ECOLOGICAL FOOTSTEP

Due to new, stricter environmental regulations, the foam industry is changing. Regulatory limits are being tightened and customer requirements are rising. The need for chlorine- and thus halogen-free end products is continuously gaining in importance.

由于新的环境法规愈加严格,泡绵行业也正随之发生变化。监管限制正在收紧,客户的要求也在提高,因此,对无氯及无卤素终端产品的需求变得越来越突出。

Benefits:

- Halogen- and chlorine-free formulated

- Solvent-free adhesives

- Eco-Label ready

优势:

- 无卤素和无氯配方

- 无溶剂

- 已获得环保标签

04

SIMALFA®助力流水线生产

Inline Production with SIMALFA®

Pack mattresses immediately after production with the especially for the inline production designed SIMALFA® adhesives. Maximize efficiency, reduce storage space requirements (no temporary storage) and increase process reliability at the same time. Ideal for the efficient, time-saving and cost-effective bonding of foams.

SIMALFA® 专门为流水线生产订制了一款出产线即可包装的速干胶粘剂。它可将生产效率最大化,减少对存放场地的要求(无需临时摊放),同时提高加工过程的稳定性。这是一款理想的高效、省时、省成本的海绵胶粘剂产品。

ADVANTAGES OF THE SYSTEM:

Inline production

Immediate packaging

Maximum efficiency

High process reliability

Time savings in production

Immediate packaging

No temporary storage

No memory effect

该系统的优势:流水线生产、即刻包装、效率最大化、高可靠性、节省加工时间、即刻包装、无需临时摊放、无记忆效应

应用领域:床垫生产

INLINE PRODUCTION WITH SIMALFA®

Conventionally bonded foam mattresses require several hours of drying time until the liquid content of the adhesive has vaporized so far, that a problem-free packaging is possible. Thanks to the specially designed adhesives for inline production, the drying process can be significantly shortened. The SIMALFA® 360 adhesive enables immediate packaging without a “memory effect” in roll packed mattresses. This maximizes your production and minimizes your storage costs.

SIMALFA® 助力流水线生产,传统工艺粘合的海绵床垫需花费数小时的干燥时间,等待粘合剂中的水分完全蒸发后才可进行包装。这款专门为流水线生产订制的 SIMALFA® 速干胶粘剂可大幅缩短干燥过程。SIMALFA® 360粘合剂无“记忆效应”,可即刻卷包床垫。这将使您的产量最大化,同时将储存成本降至最低。

展商介绍

ALFA公司是由Emil Simmler先生于1972年创立的。他开发并推广了环保型胶粘剂,并努力推进水性胶粘剂进入全球范围并拥有了很大的市场份额。从一开始,这位拥有远见卓识的公司创始人就一直致力于公司的发展,直到今天,他的专业知识为我们如今的产品线奠定了基础。

ALFA公司是一家以创新为导向的瑞士家族企业,拥有超过50名员工,位于苏黎世Rafz地区。在瑞士和美国新泽西地区都有生产基地,我们的产品出口到90多个国家。

ALFA 公司是开发、生产和销售环保水性胶粘剂的市场领导者之一。最重要的是,在泡沫塑料加工业中,SIMALFA®系列产品被广泛使用并享有很好的口碑。除分散胶粘剂外,我们还销售热熔胶,用于各种行业,如包装行业。

作为一家领先的环保无溶剂胶粘剂制造商,我们打算在未来制定标准,为客户提供直接的附加值。我们努力减少全球溶剂的排放,开发新的市场,用我们的产品和技术支持客户,这是我们所做的工作背后的持续驱动力。

为了更好的体验

请竖屏浏览