Laura Zhang

Sales & Marketing,HJT EXPO

| Phone | +86 10 58677126 |

|---|---|

| Fax | +86 10 58677126 |

| wenting.zhang@interfoam.cn | |

| Address | Rm 2003, Building A,Timecourt, Chaoyang District, Beijing, China |

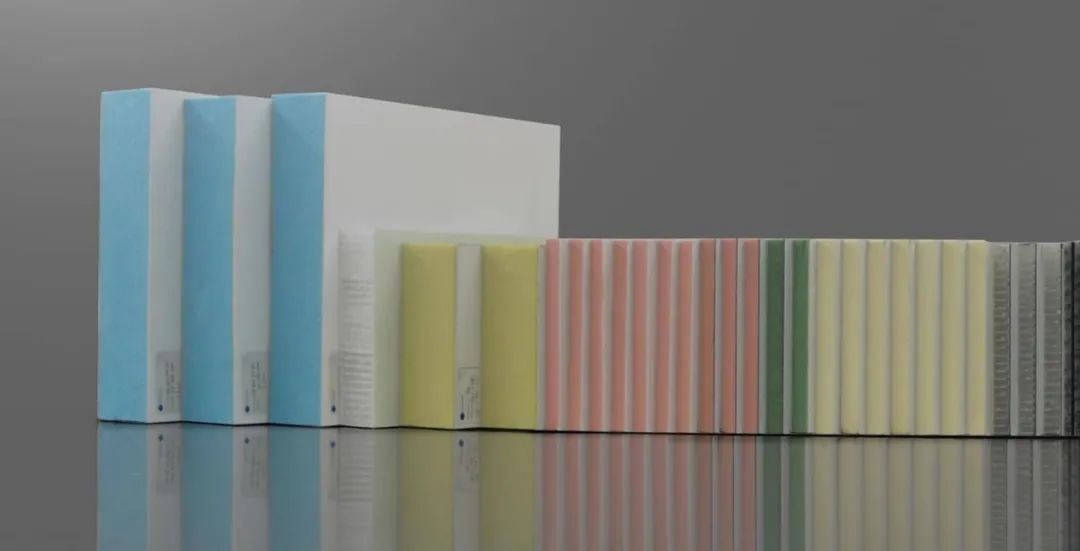

If high stiffness and low weight are key requirements for industrial manufacturing and component design, then rigid foam core materials are the best candidate. Foam core materials are widely applied in sandwich-structured composite materials with its unique properties, showing robust "hard core" strength in such industries as green building, automobile, aerospace, marine, wind energy, and sports, thus laying a solid foundation of high-performance materials for the development of the national economy.

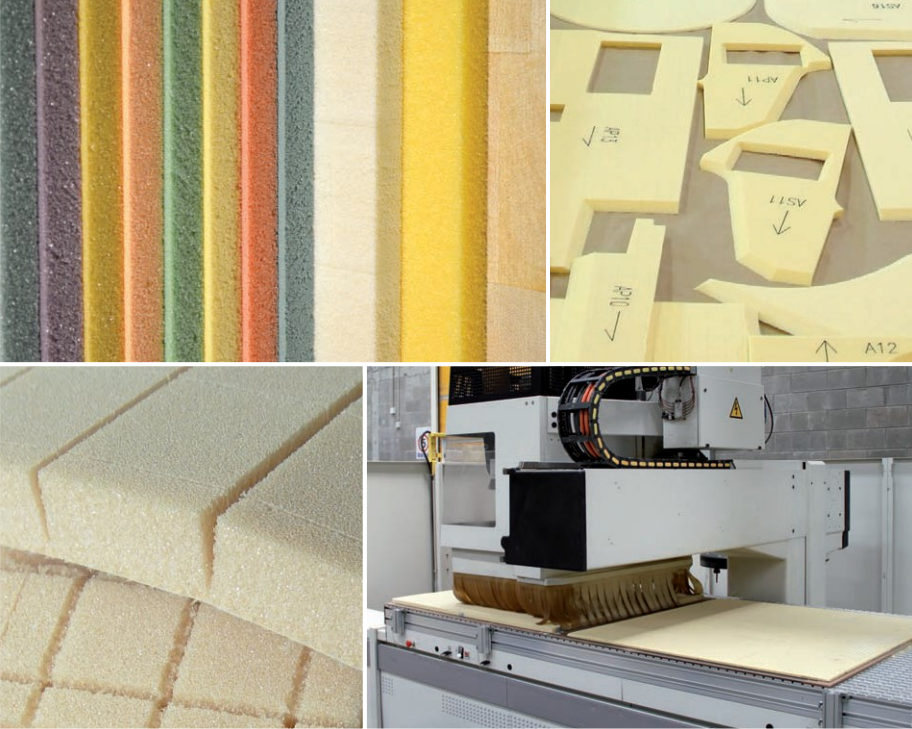

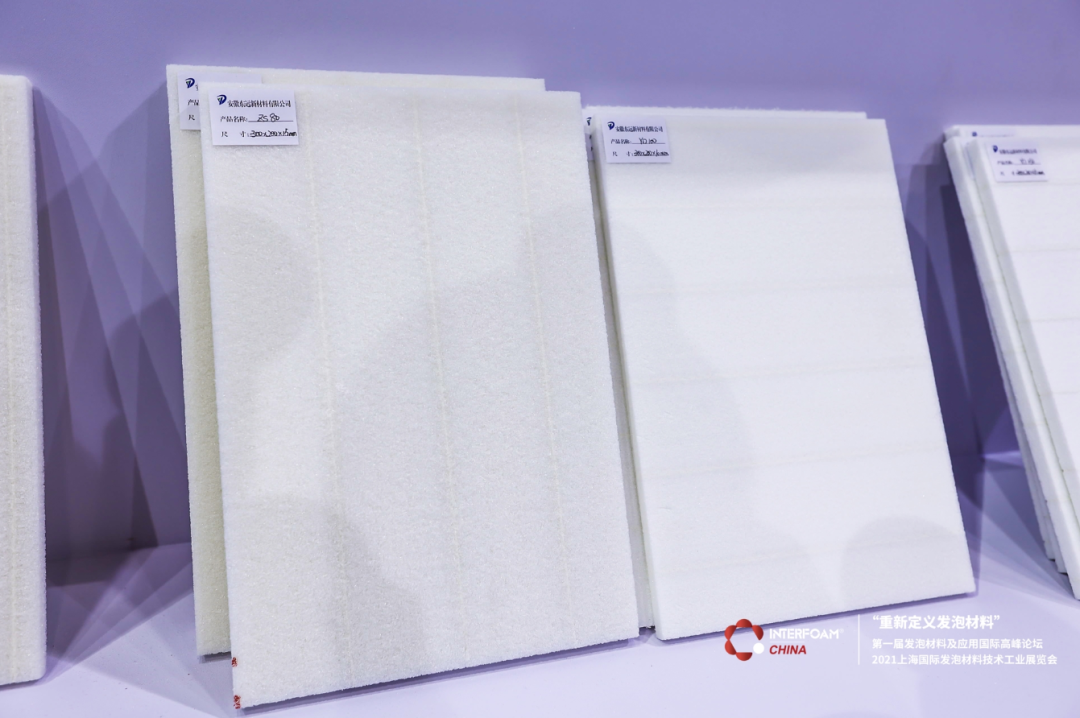

As one of the most common core materials, rigid foams are the ideal choice for manufacturing various types of boards, including flat (or free), lightweight and rigid ones. All kinds of foam core materials can provide additional desired features to final products, such as cost-efficiency, low water absorption, good sound and thermal insulation, FST resistance or insulation. They are components with a very high stiffness-to-weight ratio and a high flexural strength-to-weight ratio. In particular, the boards made of lightweight, high-density structural foam core materials have higher compressive strength and crush resistance than those made of ordinary non-structural foam core materials.

The polymer foams used to produce core materials are made of diversified rigid expansion materials, also known as rigid foams, including the expansion materials, foam metal structures and other composite structural materials of polyurethane (PU), polyvinyl chloride (PVC), extruded polystyrene (XPS), polymethacrylimide (PMI), polyetherimide (PEI), polyethylene terephthalate (PET), styrene acrylonitrile (SAN), polyethersulfone (PES), polyimide (PI).

Foam core materials are widely used in the manufacture of sporting goods, such as windsurfing board, kiteboards, wakeboards, snowboards, racing parts, beach rackets, etc.

The requirement for high quality and low cost of product lifespan has turned manufacturers' attention to structural foam core materials. Composites with rigid foam core materials can help manufacturers reduce fuel consumption and increase payload. Aircraft interiors, cabin side walls, trunks, head and galley access, crew rest areas, bulkheads and seat shells are commonly made from high-stiffness foams.

Sandwich composites with foam cores support better light-weight structure design, and its development is driven by less fuel consumption, higher payloads and a positive impact on the environment. Structural foam cores are used in structural components such as floors for high-speed train and automobiles, body side protection strips, instrument panels and armrests. Structural foam cores of special flame retardant grade are commonly used in private vehicles and public transportation as they can prevent fire, smoke and toxicity.

Weight, quality, cost and impacts on the environment are crucial factors when building a small boat or luxury yacht. Rigid foam cores are lightweight materials, having excellent mechanical property, consistency and moisture resistance. Therefore, they are commonly seen in marine applications, especially hulls, bulkheads, decks, hatches, interior parts such as floors and walls.

Every application on the sea floor requires high-performance equipment for safety as it is a very challenging environment. Structural foam cores are suitable for its high strength, low weight and excellent buoyancy.

Light weight, high strength, energy efficiency, flexible design, and durability are the greatest advantages of rigid foams in the manufacture of antennas, radomes, and antenna tower structures in radar and telecommunication industries.

The requirement for durable and heavier turbine blades has driven manufacturers to use core materials, primarily high-performance structural foam cores, which can produce larger, stronger, stiffer, but more lightweight blades. Thus, structural foam cores will help reduce costs and increase the efficiency of wind power plants.

——————————————————————————————————————————————————

Interfoam China is a professional exhibition for the whole foam industrial chain in Asia, and is an international event that cannot be missed by the professionals from foam industry all around the world.

Interfoam China focuses on the latest production, technology & equipment, new techniques, new trend, and new application in foam industry, and spare no effort to provide a professional platform integrating technologies, trade, brand display, and academic exchanges for its upstream and downstream as well as vertical application industries, thus promoting industrial sustainability.

Sales & Marketing,HJT EXPO

| Phone | +86 10 58677126 |

|---|---|

| Fax | +86 10 58677126 |

| wenting.zhang@interfoam.cn | |

| Address | Rm 2003, Building A,Timecourt, Chaoyang District, Beijing, China |

Please browse vertically for better experience.